- Top

- What is SELFOC®?

What is SELFOC®?

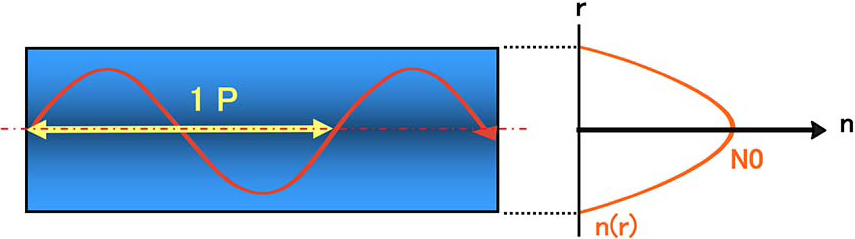

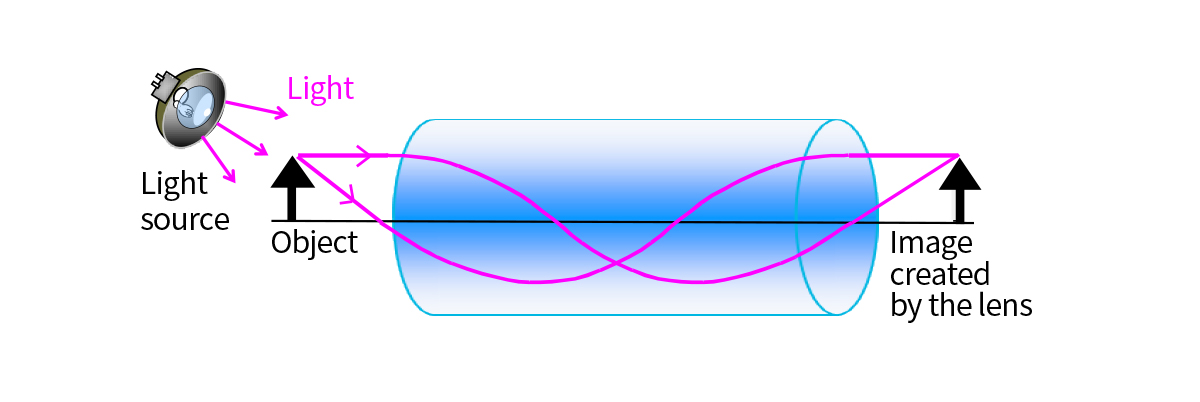

Light travels straight through a uniform medium, but bends its path towards the area of a larger refractive index within a non-uniform medium. By using this principle and changing a refractive index distribution in the glass rod, it is possible to make light meander through it.

SELFOC® (Self Focusing) is a thin glass rod or filament whose refractive index decreases in a parabolic shape from the central to the peripheral areas.

It can transmit light beams in a sinusoidal shape. In addition, it works as a highly functional lens without using a spherical process.

1P

: 1 pitch length

r

: Radial direction

n

: Refractive index

N0

: Central refractive index

n(r)

: Refractive index in radial direction

√A

: Refractive index distribution constant

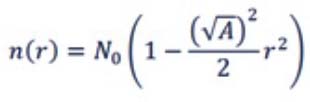

P (pitch) is the periodic length of light rays that meander through the lens and is represented by P = 2π/√A. The refractive index n(r) at the position of radius r, with the center of the lens as the origin, is expressed by the following equation.

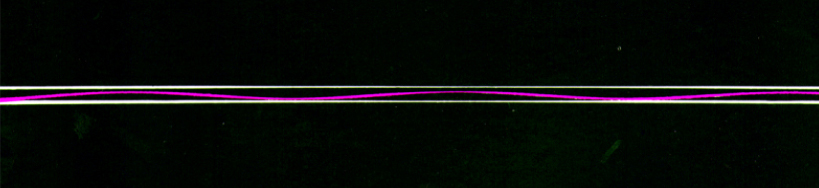

Ray trajectory in SELFOC®

Usage of SELFOC®

SELFOC® is able to simultaneously transmit many types of light beams within a narrow space without disrupting the phases. Furthermore, when cut short, it becomes a highly functional lens (general name: GRIN [Gradient Index] lens) with superior image transmission capabilities. It is used as a key component in a broad range of applications such as image scanners, LED printers, automated optical inspection machines, optical communication devices, micro lenses and relay lenses for image transmission, and Optical Coherence Tomography (OCT).

History of SELFOC®

SELFOC® has a long history. In 1965, we began research and development of glass optical fiber as an optical transmission line at the Amagasaki Research Center. In 1967, we began researching ways to transmit light within a glass fiber without deterioration. After countless experiments, NSG Group successfully developed an innovative method to form parabolic refractive index distribution in a glass rod and announced the discovery in 1968. The invention of SELFOC® drew worldwide attention. Since then, the Group has been continuing to research, develop, and manufacture a variety of optoelectronic technologies/products as a pioneer in the micro-optics field.

Manufacturing process

The manufacturing process of the SELFOC® lens consists of spinning and ion exchange processes.

1

Spinning process

Glass raw materials are melted and drawn down to produce glass rods.

2

Ion exchange process

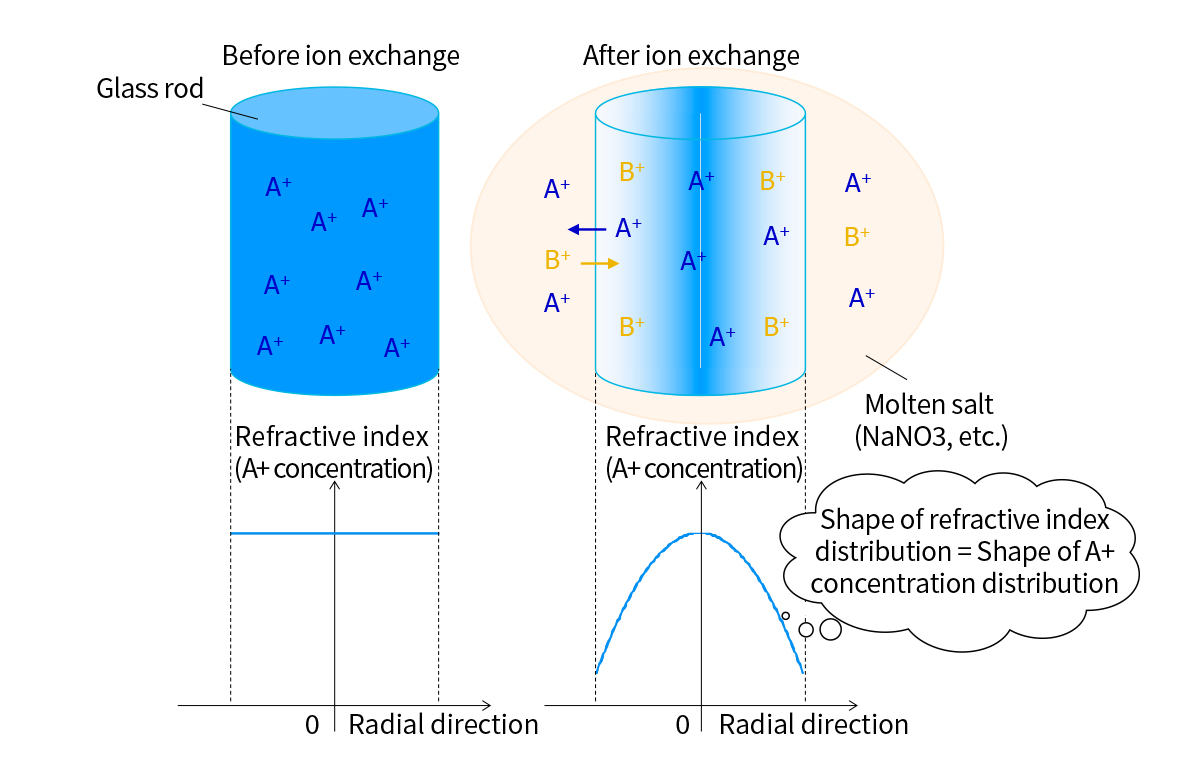

This is the most important process in the manufacture of SELFOC® lenses. Glass rods are submerged into a bath of NaNO3 molten salt for the ion exchange treatment. This process forms a parabolic distribution of refractive index in a radial direction. In the ion exchange process, high-refractive index monovalent cations (A +) existing in the glass rod elute into the molten salt, and low-refractive index monovalent cations (B +) infiltrate into the rod from the molten salt. This process forms the parabolic refractive index distribution where it is highest at the light axis (center line) and become increasingly lower at the periphery (Fig. 1). When the refractive index distribution is formed, light travels, meandering through a glass rod and the rod functions as a lens. (Fig. 2).

Fig. 1 Refractive index distribution in a glass rod before and after ion exchange

Fig. 2 Ray trajectory in glass rod

Mass production and

sample production

SELFOC® supports small to large scale manufacturing under strict quality control in order to provide a consistent supply of high-quality products. We can provide samples for trial production and evaluation in order to meet customers’ various specifications.